PACKAGING: Inclined Plane Friction Tester

Categories

- IGT TESTING SYSTEMS

- GRAPHIC ARTS

- PAPER

- INKS & CHEMICALS

- PACKAGING

- OTHERS

- EMCO

- TECHLAB SYSTEM

- QS FIBRE

- HUME HOOD

- KG BEARING

- CLEANER DIESEL FUEL (DEBUG)

- PULSARLUBE

- Electrochemical

- Electromechanical

- Mechanical

- RS COMPONENT

- LEROY SOMER

- METAL PROTECTOR

- OXYGUARD

- PROBES

- HAND-HELD

- MONITORING & CONTROL

- SINAPSE - Print Simulators

- GEOTECHNICAL TESTING EQUIPMENT

- BATU ALAM DARI JAWA TIMUR

- LAIN-LAIN

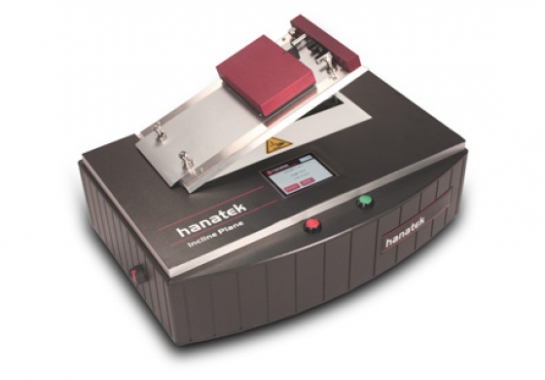

The Hanatek Inclined Plane Friction Tester is a low cost but extremely accurate instrument for determining the static friction coefficient of flat surfaces.

Designed for use in the packaging industry to measure the static slip of unprinted carton board, printed cartons or plastic films and their coatings, the instrument is suitable for measuring other products including leather, textiles and paper.

Results are displayed in both coefficient of friction and slip angle with batch analysis and can be output to the optional Hanatek results printer.

Features

- Multiple tests with statistical analysis

- Simply measures static coefficient of friction

- Accurate slip measurement- readout to 0.1°

- Precision servo motor for repeatable readings

- Auto stop and auto-platen return

- Available with a choice of sleds for relevant ASTM / TAPPI standards

- Results displayed in COF and slip angle

- Results label printer

Specifications

| Specifications | Detail |

|---|---|

| C.O.F | ISO 8295, ISO 15359, BS 2782 pt 8 |

| Power | 110/240V 50/60 Hz |

| Sleds | 200g |

| Weight | 5kg |

| Size | (H) 180 x (W) 225 x (D) 300mm |

Standards

- ASTM D4918 Standard Test Method for coefficient of static friction of uncoated writing and printing paper by use of the inclined plane method

- TAPPI T815 Coefficient of static friction (slide angle) of packaging and packaging materials (including shipping sack papers, corrugated and solid fiberboard) (inclined plane method)

Applications

Typical applications for the Inclined Plane Friction Tester include:

- Printed cartons

- Flexible packaging

- Printing, Rubber

- Linoleum, Leather, Paper

- Foils, Coatings, Plastics

- Textiles, Composites

Who measures slip/friction?

Friction testing is used in the packaging industry to measure the slippyness of a product, with the aim of predicting feeding and runnning speed on an automatic gluing, erecting, filling or packaging line.